Fiber Cement Board, as an innovative building material that integrates modern manufacturing technology with eco-friendly principles, is becoming a pivotal force in the green transformation of the construction industry. Amidst the trend of traditional building materials being phased out of the market due to issues such as susceptibility to aging and lack of environmental friendliness, it offers a more sustainable and efficient solution for modern construction with its outstanding overall performance.

I. What is a Fiber Cement Board? Core Components and Production Process

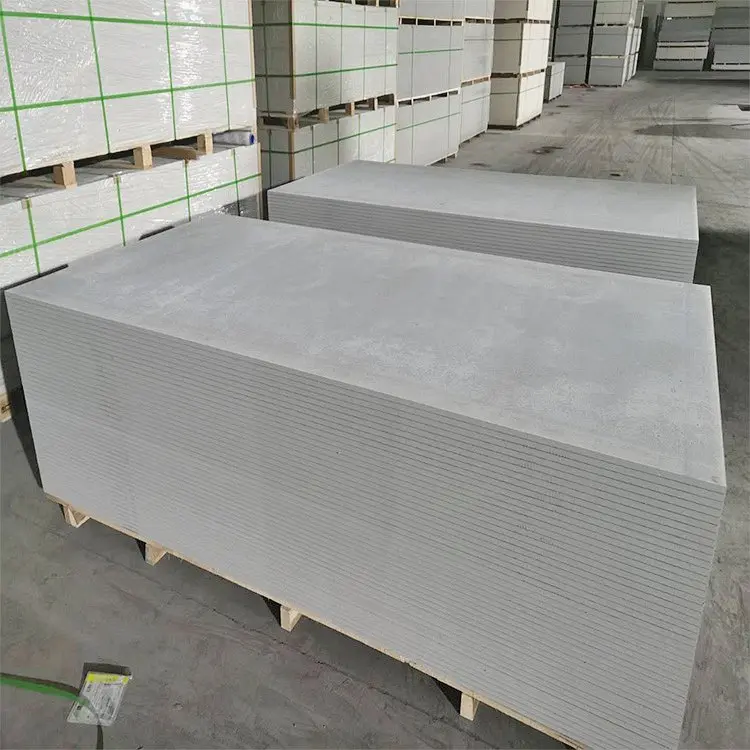

Fiber cement boards are manufactured using high-grade, high-specification cement as the base material, combined with fiber reinforcement materials and specialized auxiliary additives for modification. They undergo multiple technical processes including advanced molding, pressing, and autoclave curing, ultimately resulting in a stable-performance building panel.

Based on density differences, these boards can be categorized into two main types: medium density and high density. They exhibit an extremely low wet expansion rate of approximately 0.25%, ensuring exceptional dimensional stability to fully meet the usage requirements of diverse architectural scenarios.

II. Core Advantages of Fiber Cement Boards: 6 Highlights Outperforming Traditional Materials

Compared to traditional materials like wooden boards and PVC siding, fiber cement boards offer significant performance advantages, addressing fundamental pain points of conventional materials at their root. The core highlights are primarily reflected in the following six aspects:

III. Multi-Scenario Applications of Fiber Cement Boards: Covering Diverse Architectural Needs

Fiber cement boards have wide-ranging uses, adapting to various architectural scenarios, making them a versatile new type of building material.

.webp)

IV. Choosing Our Fiber Cement Boards: Dual Assurance of Quality and Service

As a professional manufacturer of fiber cement boards, we consistently adhere to the bottom line of quality. From raw material procurement to every step of the production process, we have established a stringent quality control system to ensure every batch of fiber cement boards complies with national quality standards and environmental requirements.

Choosing fiber cement boards means choosing an environmentally friendly, durable, and efficient building solution. Please feel free to contact us anytime to obtain exclusive product quotations and application plans!

Our technical staff is available 24/7 for support and fast response, giving full advice on your products and sharing engineering knowledge. Whether you order or not, we’re always here to support your business.