Through-Color Fiber Cement Board: The Future of Durable and Aesthetic Building Materials

Introduction

The construction industry is constantly evolving, with innovative materials redefining architectural possibilities. Among these advancements, through-color fiber cement board has emerged as a game-changer for both exterior and interior applications. Unlike traditional cement boards that rely on surface coatings, through-color boards feature pigments infused throughout the material, ensuring long-lasting vibrancy and durability.

This article explores the manufacturing process, key benefits, and diverse applications of through-color fiber cement board, making it a top choice for architects and builders worldwide.

What Is Through-Color Fiber Cement Board?

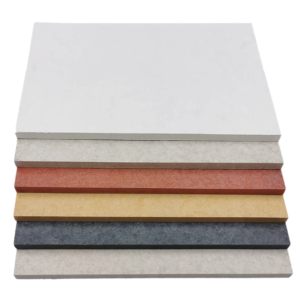

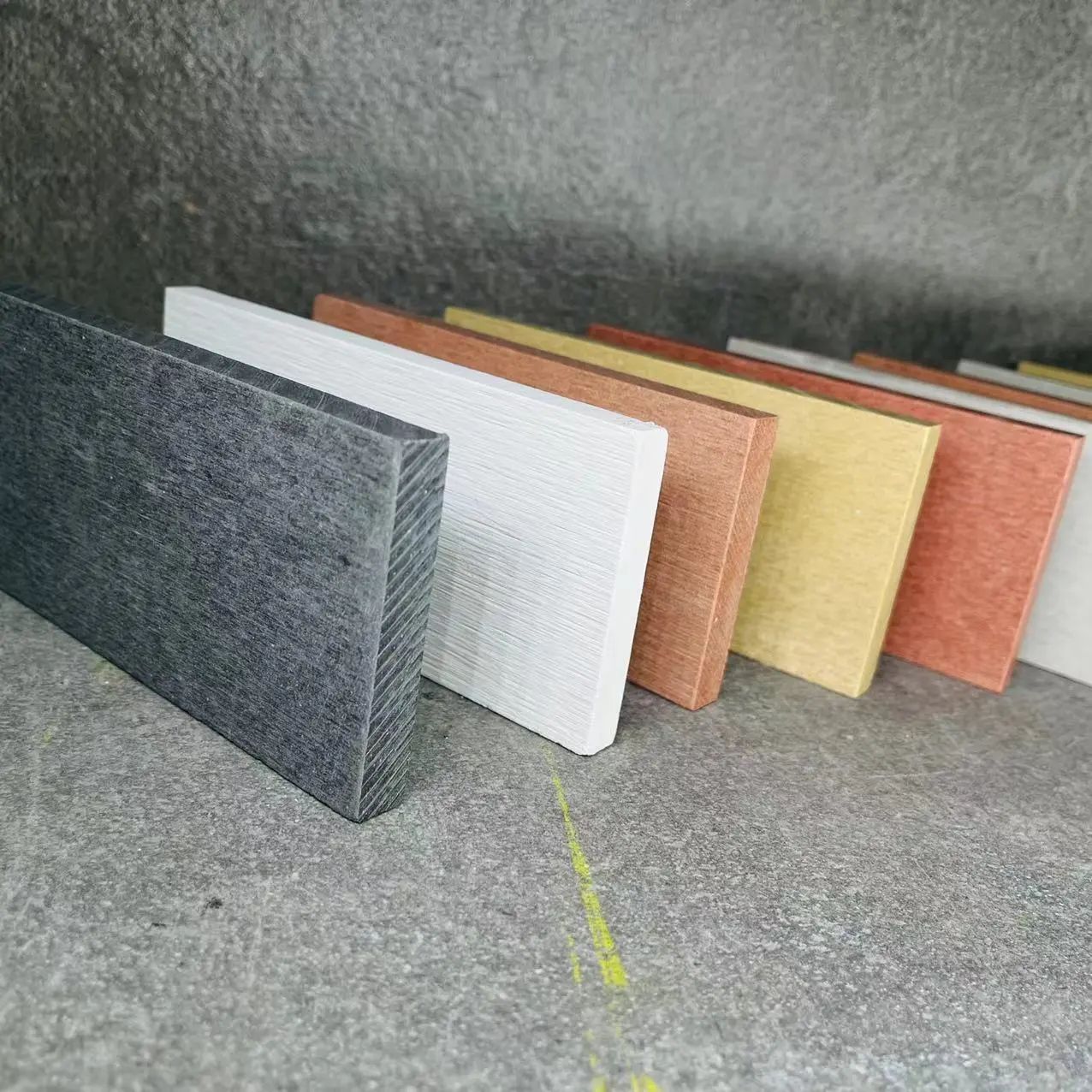

Through-color fiber cement board is a high-performance building material composed of cement, natural fibers, and UV-resistant pigments. Unlike painted or laminated boards, the color penetrates the entire thickness, eliminating the risk of fading, chipping, or peeling. This results in a low-maintenance, weather-resistant solution perfect for modern construction.

How Through-Color Fiber Cement Boards Are Made

1. Premium Raw Materials

The production of through-color fiber cement board begins with carefully selected ingredients:

Cementitious Matrix – A blend of Portland cement, silica, and specialized additives ensures strength and durability.

Reinforcing Fibers – Cellulose or synthetic fibers enhance flexibility and impact resistance.

UV-Stable Pigments – Unlike surface paints, these pigments are mixed into the slurry, guaranteeing uniform color that won’t fade.

2. Mixing & Forming

The raw materials are combined into a slurry, which is then pressed into sheets of varying thicknesses. Advanced manufacturing techniques ensure consistency in density and structural integrity.

3. Curing & Finishing

The boards undergo a high-pressure curing process, strengthening the cement matrix. The result is a lightweight yet incredibly durable panel ready for architectural use.

Key Benefits of Through-Color Fiber Cement Board

1. Fade-Resistant & Consistent Color

Since the pigment is embedded throughout the board, the color remains vibrant for decades, even under direct sunlight. This eliminates the need for repainting, saving time and maintenance costs.

2. Exceptional Durability

Moisture-resistant – Ideal for humid climates and wet conditions.

Fireproof – Non-combustible, enhancing building safety.

Pest-resistant – Unlike wood, it won’t rot or attract termites.

3. Superior Weather Resistance

Through-color fiber cement boards withstand extreme temperatures, heavy rain, and UV exposure without warping or cracking, making them perfect for exterior cladding.

4. Low Maintenance

A simple rinse with water and mild detergent is all that’s needed to keep these boards looking new—no sealing, staining, or frequent touch-ups required.

5. Design Flexibility

Available in a wide range of colors and textures, these boards can mimic wood, stone, or sleek modern finishes, offering architects unlimited creative possibilities.

Applications of Through-Color Fiber Cement Board

1. Exterior Cladding & Facades

Thanks to their weatherproof and impact-resistant properties, these boards are widely used in:

Residential homes

Commercial buildings

Industrial structures

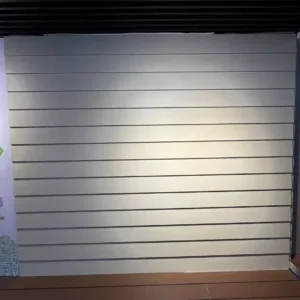

2. Interior Wall & Ceiling Panels

Their fire-resistant and soundproof qualities make them ideal for:

Feature walls

Office partitions

Hotel lobbies

3. Sustainable & Modern Architecture

As a green building material, through-color fiber cement boards are often used in eco-friendly projects due to their longevity and minimal environmental impact.

Reviews

There are no reviews yet.