Fire and Blast Resistant Panels: The Ultimate Protective Building Solution

What Are Fire and Blast Resistant Panels?

Fire and blast resistant panels are specialized construction materials designed to provide superior protection in extreme conditions. These panels offer:

– Fire resistance for up to 6 hours

– Blast resistance against pressures up to 2.3 bar

– Excellent durability in harsh industrial environments

These panels are ideal for use in:

– Oil and gas facilities

– Chemical processing plants

– Military and government buildings

– High-security structures

How Fire and Blast Resistant Panels Work

Advanced Composite Construction

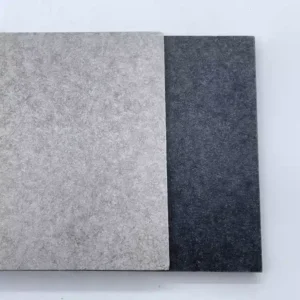

These panels feature:

– Two protective metal face layers (available in galvanized or stainless steel)

– A reinforced cement core for maximum strength

– Mechanical bonding for structural integrity

Key Performance Characteristics

– Fireproof: Tested against hydrocarbon fires with H120 rating

– Explosion-resistant: Maintains structural stability under blast conditions

– Impact-resistant: Withstands harsh industrial environments

– Low maintenance: Long-lasting performance with minimal upkeep

Additional Advantages

– Sound insulation properties

– Corrosion-resistant options available

– Prefabricated for quick and easy installation

Common Applications

Fire-Rated Walls and Barriers

These panels protect critical infrastructure from fire and explosions in:

– Industrial tunnels

– Power generation facilities

– Petroleum refineries

Blast-Resistant Ducts and Enclosures

Specialized panel systems prevent fire and shockwave spread in:

– Ventilation systems

– Utility conduits

– Process piping

High-Temperature Industrial Protection

The panels provide shielding in extreme environments such as:

– Steel manufacturing plants

– Foundries

– Chemical processing facilities

Security and Military Applications

Reinforced panel systems are used for:

– Protective bunkers

– Armories

– Government defense installations

Technical Specifications

Standard panel size: 1200mm x 2500mm (4ft x 8ft)

Available thicknesses: 6mm (1/4 inch) or 9.5mm (3/8 inch)

Surface finish options: Galvanized (Z275/G90) or 316 stainless steel

Fire resistance rating: Up to 6 hours (hydrocarbon fire tested)

Blast resistance rating: Up to 2.3 bar pressure

Benefits of Fire and Blast Resistant Panels

– Enhanced safety beyond standard fireproofing systems

– Exceptional durability against moisture, impacts, and corrosion

– Simplified installation process

– Minimal maintenance requirements

Conclusion

Fire and blast resistant panels provide unmatched protection for high-risk environments. These advanced building materials ensure safety, durability, and regulatory compliance for industrial, military, and commercial applications.

For customized solutions, consult with a specialist to determine the optimal fire and blast protection system for your specific requirements.

This informational guide assists engineers, architects, and safety professionals in selecting appropriate protective panel systems for critical infrastructure projects.

Reviews

There are no reviews yet.