The New Standard for Fire Duct Protection

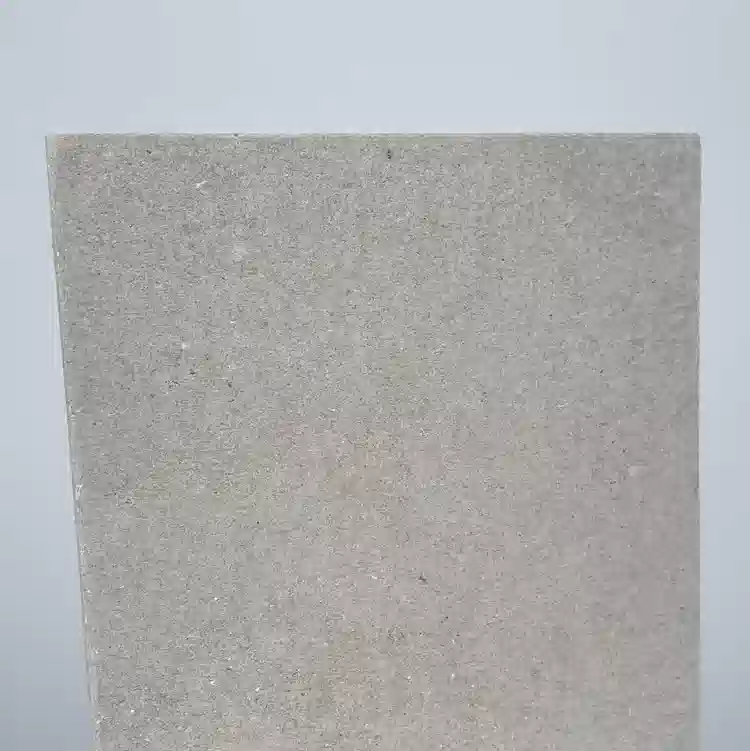

Calcium silicate fireproof boards are becoming the preferred material for fire duct encasement. As professional manufacturers, we analyze the unique advantages of this material.

Why Choose Calcium Silicate Boards?https://fibercement-boards.com

Basement Environment Test Comparison

| Material | Condition After 3 Years | Fastener Status |

|---|---|---|

| Calcium Silicate Board | Like new | No rust |

| Magnesium Oxide Board | Surface powdering | Visible rust |

Core Technical Specifications

Installation Advantages

✓ Easy cutting: Processable with standard tools

✓ Quick installation: 30% faster than soft materials

✓ Tight joints: Special sealing technology

✓ Low maintenance: Lifetime replacement-free

Cost-Effectiveness Analysis

Though 20% higher priced than MgO boards, consider:

Professional Installation Guide

Why Choose Us?

Our technical staff is available 24/7 for support and fast response, giving full advice on your products and sharing engineering knowledge. Whether you order or not, we’re always here to support your business.